In the rapidly evolving landscape of pharmaceutical manufacturing, the integration of advanced technologies has become imperative for enhancing efficiency, reducing costs, and ensuring compliance with stringent regulations. Among these technologies, the concept of the "digital twin" has emerged as a transformative force. A digital twin is a virtual representation of a physical entity, allowing for real-time monitoring, simulation, and optimization of processes. By leveraging digital twin technology, pharmaceutical plants can significantly improve their operations. Coupled with smart manufacturing applications, these innovations pave the way for a more agile and responsive industry.

Exploring Digital Twin Technology in Pharma Manufacturing

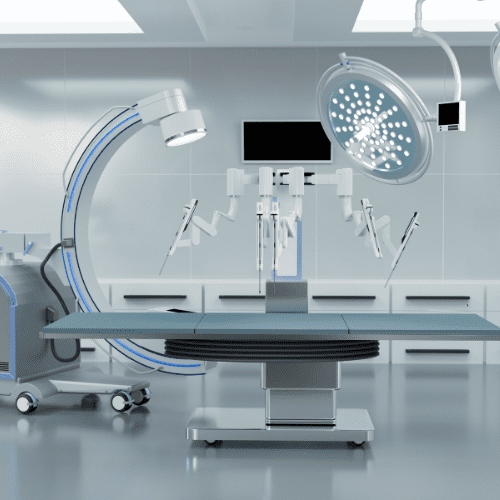

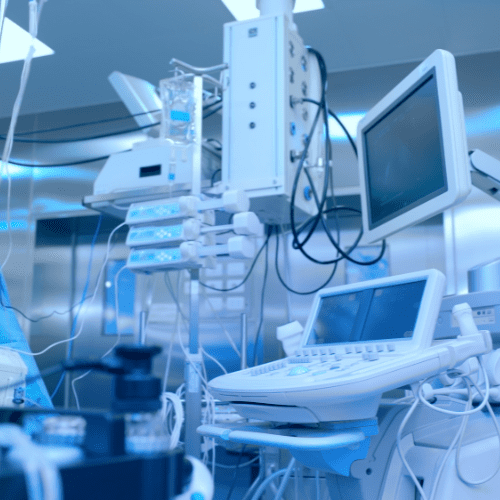

Digital twin technology provides pharmaceutical manufacturers with a powerful tool to visualize and simulate their production processes. By creating a digital counterpart of a physical manufacturing unit, stakeholders can track real-time data on equipment performance, product quality, and overall operational efficiency. This level of visibility enables proactive decision-making and timely interventions, minimizing downtime and enhancing productivity. For example, if sensors detect an anomaly in machinery, the digital twin can simulate potential outcomes of various corrective actions, allowing operators to choose the most effective solution without affecting actual production.

Furthermore, digital twins facilitate continuous process improvement through data analytics. By aggregating historical and real-time data, these virtual models can identify trends, predict potential failures, and suggest optimizations. In a pharmaceutical setting, where product quality and compliance with regulatory standards are paramount, the insights gained from a digital twin can help ensure that processes remain within defined parameters. This not only aids in maintaining high-quality standards but also accelerates the approval process for new drugs, as a well-optimized manufacturing process can yield more consistent results.

Moreover, digital twins can enhance training and onboarding in pharmaceutical plants. New employees can interact with the virtual model to understand complex systems and processes without the risk of operational disruptions. This immersive training approach not only shortens the learning curve but also cultivates a workforce that is more adept at utilizing advanced technologies. As the pharmaceutical industry continues to embrace digital transformation, the role of digital twins will be crucial in shaping a future that is both efficient and compliant.

Smart Manufacturing Applications Transforming Pharma Plants

Smart manufacturing applications are redefining the operational landscape of pharmaceutical plants by integrating IoT (Internet of Things), AI (Artificial Intelligence), and data analytics. These technologies enable real-time monitoring and control of production processes, allowing manufacturers to respond swiftly to changing conditions. For instance, IoT devices can collect data from various stages of production, providing insights that help optimize resource allocation, improve scheduling, and reduce waste. This level of connectivity ensures that pharmaceutical companies can maintain high production standards while simultaneously reducing operational costs.

In addition, AI-driven analytics play a pivotal role in smart manufacturing by predicting trends and automating decision-making processes. Machine learning algorithms can analyze vast amounts of data derived from manufacturing systems, enabling predictive maintenance that minimizes downtime and extends equipment lifespan. For pharmaceutical companies, where equipment failure can lead to significant financial losses and compliance issues, this proactive approach is invaluable. Smart manufacturing applications can also facilitate batch tracking and traceability, ensuring adherence to regulatory requirements throughout the product lifecycle.

Furthermore, the integration of smart manufacturing with digital twins creates a synergistic effect that amplifies the advantages of both technologies. By combining real-time data from smart manufacturing applications with the predictive capabilities of digital twins, pharmaceutical manufacturers can simulate various production scenarios and optimize their workflows. This harmonious relationship not only enhances operational efficiency but also fosters innovation. As pharmaceutical companies strive to bring new therapies to market faster, the convergence of smart manufacturing and digital twin technology offers a robust framework for achieving these ambitious goals.

The adoption of digital twin technology and smart manufacturing applications in pharmaceutical plants marks a significant step towards a more efficient and resilient industry. By leveraging these advanced technologies, manufacturers can optimize their processes, enhance product quality, and ensure compliance with regulatory standards. As the pharmaceutical landscape continues to evolve, the synergy between digital twins and smart manufacturing will play a crucial role in shaping the future of drug production. Embracing these innovations not only positions pharmaceutical companies for success today but also prepares them for the challenges and opportunities of tomorrow.